A variety of demonstrations over the years have shown the capabilities that atomically thin materials can bring to electronics—extremely small size, excellent performance, and some distinctive properties. But almost all of these demonstrations required that the electronics being tested were essentially assembled by hand. Materials like graphene are often placed on a surface at random, and then the wiring needed for it to function is built around that location. It's not exactly a recipe for mass production.

To the extent there has been some progress, it has been limited. One of the more recent efforts involved using graphene and molybdenum disulfide to make the transistor with the smallest gate length. In this case, the two atomically thin materials had to be placed carefully but not precisely. Any excess material was etched away, and a key feature was made by cutting through the graphene sheet.

This week saw a somewhat different take on constructing these minuscule devices: chemistry. A research team linked up the two materials used in the earlier study, graphene and molybdenum disulfide, using a single bridging molecule that could react with each of them. The chemistry of the bridging molecule also influenced the behavior of a device made using this approach.

Two-for-one

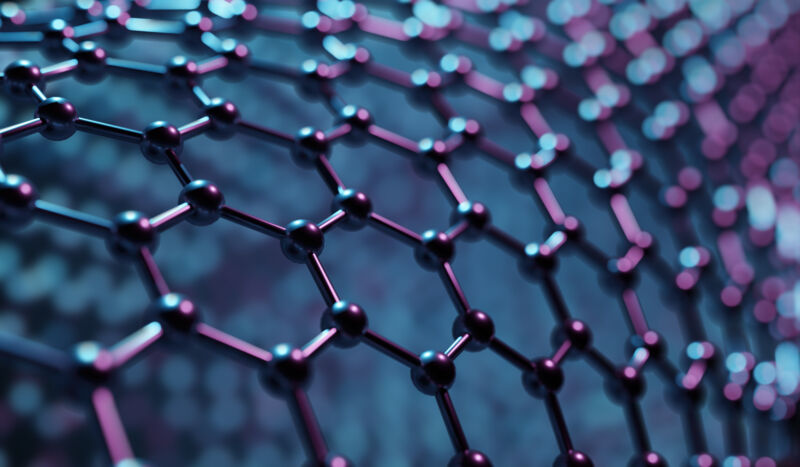

Graphene and molybdenum disulfide form sheets that are only one atom thick—all the chemical bonds holding the sheet together force it into a planar structure. They make a useful combination because they have different properties. Molybdenum disulfide is a semiconductor, while graphene usually conducts electricity well (although it can be converted into a semiconductor given the right environment). Normally, devices involving the two materials are built simply by laying one on top of the other. Weak interactions called Van der Waals forces will hold them together.

The group behind the work here, based in Spain, decided to try to build something a bit stronger. Many chemicals have been identified that can break the in-plane bonds of one or the other of these materials and chemically attach to the sheet's surface. At high enough levels, this reaction would cause the sheet to come apart. But as long as levels of these reactions are kept low enough, the sheet will remain intact and have a sparse coating of the reactive chemical.

The new work aims to create a single molecule that acts as a bridge between graphene and molybdenum disulfide. At one end of the bridge, there's a chemical group that reacts with molybdenum disulfide. On the other, there's a chemical group that interacts with graphene. In between is just a short, unreactive benzene ring.

Starting with some molybdenum disulfide flakes, the researchers ran a reaction that linked the bridge to the flake. Afterward, the flakes were placed in with graphene sheets, where the other end of the bridge molecule reacted with the graphene. The result was a graphene sheet decorated with molybdenum disulfide flakes, with the two connected via the bridge molecule.

An altered device

To make a device out of the linked material, the graphene sheet was placed on a silicon substrate and flanked by electrodes. The silicon could be used to control the flow of current across the graphene from one electrode to the other. This allowed the researchers to test its behavior in various states of chemical alteration.

With the silicon carrying enough charge to convert the graphene to a semiconductor, simply laying molybdenum disulfide across it with no chemical bridge would lead to the presence of more electrons in the graphene. This would make it an n-type semiconductor (n for negative). Linking the bridge molecule to graphene on its own would, by contrast, lead to electrons being pulled from the graphene, converting it to a p-type semiconductor (p being positive).

With the whole combination of graphene-bridge-molybdenum disulfide, the two chemicals linked to graphene partly offset each other. The bridge molecule still converted graphene to a p-type semiconductor, but the effect was weaker due to the presence of the molybdenum disulfide.

So, the work provides a nice demonstration that it's possible to fine-tune the conductive property of graphene by attaching other chemicals to it. It may be feasible to build a large library of bridge molecules that alter the graphene's behavior in different ways.

The work also suggests that it's possible to build functional structures involving more than one atomically thin material using chemistry. For example, it could be viable to lay down a sheet of graphene, etch away anything that's not needed, and then use chemistry to link another atomically thin material to it. This could potentially get around the issue of materials randomly placing themselves on what's supposed to be a compact device.

But this paper doesn't demonstrate anything like that. The molybdenum disulfide flakes are tiny compared to the graphene sheets. So what you end up with is a graphene sheet where only a portion is covered by molybdenum disulfide—a portion that's well under half. That's enough to influence the graphene's behavior but not necessarily enough to make a device that requires extensive graphene-molybdenum disulfide interactions.

It's possible we can boost the efficiency and turn this into a manufacturing technique. But the process will need some considerable improvements before we get there.

Nature Chemistry, 2022. DOI: 10.1038/s41557-022-00924-1 (About DOIs).

reader comments

20