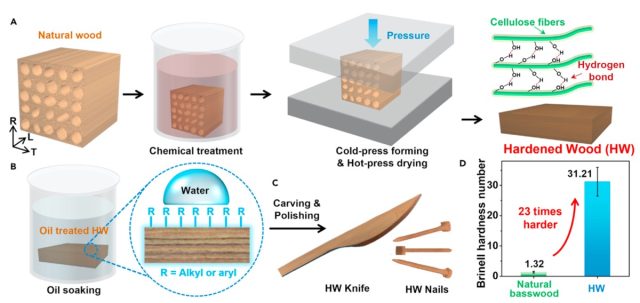

Researchers at the University of Maryland (UMD) have figured out a simple, affordable method for creating natural wood materials that are 23 times harder than typical woods, according to a new paper published in the journal Matter. They tested their hardened wood samples by fashioning a wooden knife and several wooden nails and found that the performance of both matched or exceeded that of their steel counterparts. The researchers even managed to cut a medium-well-done steak with their wooden knife as a mouth-watering proof of concept. Bonus: The knife is dishwasher safe for easy cleanup.

Why bother making wooden knives when we have perfectly good stainless steel cutlery, not to mention disposable plastic utensils? The latter, obviously, are an environmental hazard, since the nearly 40 billion plastic utensils used annually are rarely recycled because they're so small and light. And it takes a good 450 years for plastics to decompose, according to the authors. Steel and other nonrenewable hard materials—nickel-based and titanium-based alloys, for example, as well as nitrides and diamonds that are commonly used in a variety of engineering applications—are costly to manufacture because they require extreme, energy-intensive conditions (ultra-high heat and pressure).

There is a lot of interest in the materials science community to come up with cheaper, more environmentally sustainable alternatives. “When you look around at the hard materials you use in your daily life, you see many of them are man-made materials because natural materials won’t necessarily satisfy what we need,” said co-author Teng Li, a materials scientist at UMD. He and his colleagues thought that wood could be a potential replacement for plastics, concrete, and steels.

“Cellulose, the main component of wood, has a higher ratio of strength to density than most engineered materials, like ceramics, metals, and polymers, but our existing usage of wood barely touches its full potential,” said Li. That's because wood isn't nearly as strong as pure cellulose. Cellulose only makes up between 40-50 percent of wood; the rest is hemicellulose and lignin (a binding agent).

So Li et al. came up with a practical and affordable manufacturing method for creating hardened wood by removing its weaker components (i.e., the lignin). The researchers first cut raw basswood blocks into sample sizes, then soaked the samples in a water-based solution (mixed with sodium hydroxide and sodium sulfite) to fill the pores, causing the samples to sink to the bottom of the container. Three different batches of wood samples and solution were boiled at 100 degrees Celsius for two, four, and six hours, respectively, and the samples were then rinsed with deionized water to remove any lingering chemicals. (The authors note that making ceramics, for instance, requires heating the materials to a few thousand degrees Celsius.)

reader comments

381